Digital Twins in the Oil Industry: Real-Time Asset Optimization

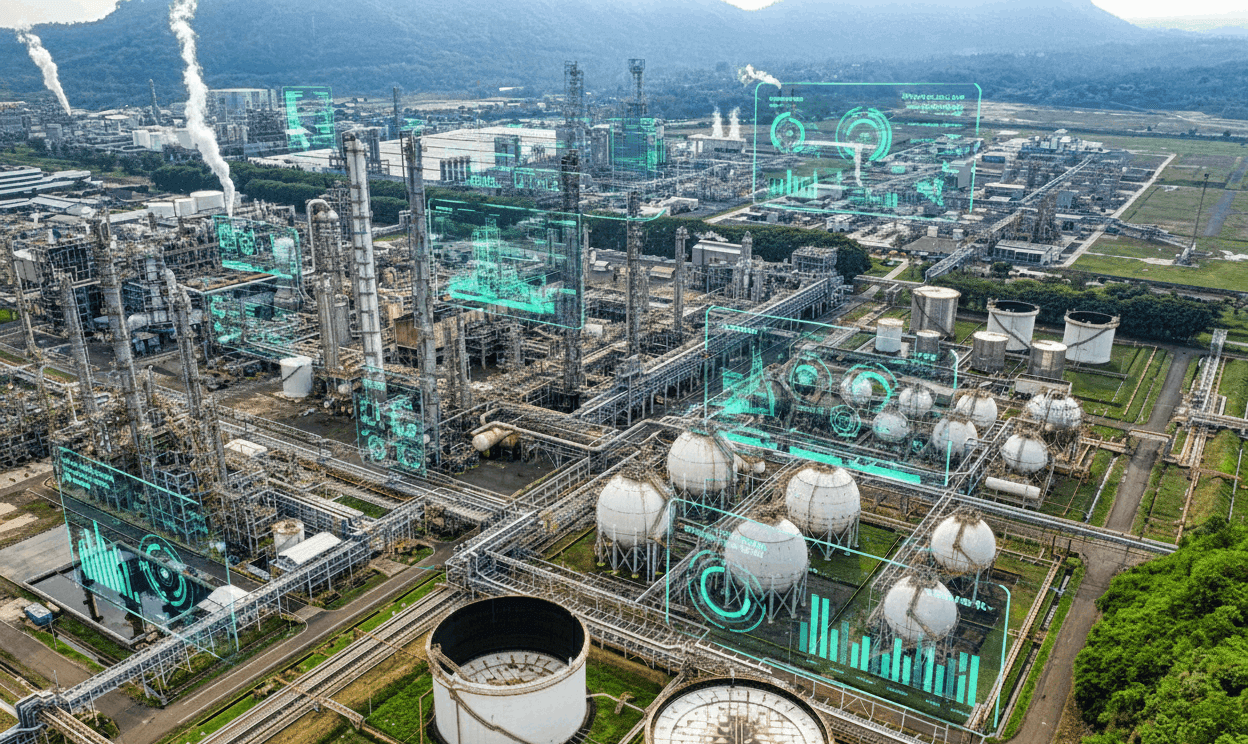

Digital twin technology is transforming how the oil and gas industry manages its most critical and complex assets. A digital twin is a virtual replica of a physical asset that continuously updates with real-time data, enabling simulations, analysis, and optimizations that would be impossible or extremely costly to perform in the physical world. This technology is enabling a new level of visibility, control, and operational efficiency.

What is a Digital Twin?

A digital twin is much more than a 3D model or static simulation. It's a dynamic, real-time virtual representation of a physical asset that integrates IoT sensor data that continuously captures operational conditions, physical and mathematical models that describe system behavior, historical data that enriches context and improves predictions, and AI algorithms that learn patterns and optimize operations.

This combination creates an environment where you can visualize the current state of the asset with total precision, simulate future scenarios to test hypotheses without risk, predict behavior under different conditions, optimize operational parameters for maximum efficiency, and train personnel in virtual environments before intervening in real equipment.

Applications in Offshore Platforms

Offshore platforms are especially suitable environments for digital twins given their cost, complexity, and isolation. A complete platform digital twin integrates production, processing, compression, and storage systems, power and electrical generation systems, safety and fire protection systems, structures and environmental conditions, and critical equipment like pumps, compressors, and turbines.

From an onshore control room, engineers can monitor the complete platform, identify optimizations without disrupting operations, simulate emergency responses, plan maintenance weeks in advance, and train new personnel in virtual operations before real deployment.

Refining Process Optimization

In refineries, digital twins enable continuous optimization of complex processes. The twin of a distillation tower can simulate how changes in temperature, pressure, or feed composition affect yield and product quality, identify optimal conditions to maximize production of specific fractions, predict coke or fouling formation before it occurs, and optimize energy consumption while maintaining product specifications.

A refinery in the Persian Gulf implemented digital twins in its main distillation towers, achieving a 3 percent increase in high-value product yield and 7 percent reduction in energy consumption in 12 months. These apparently modest improvements translated into tens of millions of dollars in annual benefits.

Reservoir Management

Digital twins of reservoirs integrate geological, seismic, and production data to create dynamic models of the reservoir. These twins allow optimizing location and sequence of new wells, adjusting water or gas injection strategies to maximize recovery, predicting reservoir behavior years into the future, identifying untapped potential zones, and making investment decisions based on multi-scenario simulations.

A North Sea operator used its reservoir digital twin to identify an optimized water injection strategy that increased the field's estimated recovery rate by 5 percentage points, equivalent to hundreds of millions of dollars in net present value.

Maintenance and Reliability

Digital twins elevate predictive maintenance to a new level. While traditional predictive maintenance identifies when components will fail, a digital twin can simulate what will happen if that component fails, evaluate the impact on the rest of the system, optimize the intervention timing considering resource availability, plan the optimal sequence of maintenances to minimize impact, and train technicians in repair procedures virtually.

An Asian petrochemical complex uses digital twins to coordinate maintenance of hundreds of interdependent equipment, reducing planned downtime by 30 percent through optimized sequencing.

Immersive Training and Capacity Building

Digital twins combined with virtual reality create exceptionally realistic training environments. Operators can practice emergency responses without real risk, learn to operate new equipment before installation, experiment with optimizations in a safe environment, and develop intuition about system behavior through accelerated simulations.

An international oil and gas company reported a 40 percent reduction in new operator training time and virtual elimination of beginner operational errors after implementing digital twin training.

Integration with Control Systems

The greatest value of digital twins is achieved when integrated with control systems to create closed loops. The twin continuously optimizes operational parameters, recommendations are automatically implemented in the control system, results update the twin creating continuous learning, and the cycle repeats thousands of times a day, constantly refining the operation.

This level of integration transforms conventional facilities into autonomous plants that continuously self-optimize.

Implementation Challenges

Creating effective digital twins presents significant challenges. Data quality and granularity determine twin precision, complex physical models require specialized expertise, computational power for real-time simulations can be considerable, and integration with legacy systems can be complex.

However, gradual approaches that begin with specific equipment or processes allow demonstrating value while building capacity. A complete plant twin isn't necessary from day one: starting with critical assets and progressively expanding is the most pragmatic path.

Enabling Technologies

Several technologies converge to make modern digital twins possible. Industrial IoT provides necessary real-time data. Cloud computing offers computational power for complex simulations. Edge computing enables local processing for real-time decisions. 5G enables transmission of large data volumes with minimal latency. And AI and machine learning continuously improve predictive models.

The growing maturity of these technologies is reducing costs and barriers to entry, making digital twins accessible to companies beyond large corporations.

Value Metrics

Leading companies measure tangible impacts. Gulf of Mexico operator achieved 12 percent increase in critical facility uptime. European refinery reduced energy consumption by 8 percent while maintaining production. Asian company improved product yield by 4 percent without hardware investment. And offshore operator reduced maintenance visits to platforms by 25 percent with better planning.

These benefits typically generate ROI in 18 to 36 months depending on implementation complexity and asset criticality.

The Future: Cognitive Digital Twins

The next generation will be digital twins that not only simulate but reason autonomously. Using advanced AI techniques, these systems will be able to generate hypotheses about observed problems, test solutions virtually before implementing them, learn not only from their own operation but from complete fleets of similar assets, and communicate in natural language with operators to explain their recommendations.

We're transitioning from digital twins as analysis tools to intelligent assistants that collaborate with human teams in continuous operation and optimization.

Implementing digital twins isn't an overnight thing. You need clean and consistent data, reliable field sensors, and people who understand both the physical process and the digital part. But when you set it up right, the difference is brutal. You're not just seeing what's happening now - you're testing future scenarios in an environment where making mistakes doesn't cost you millions.

I've seen refineries reduce energy consumption by 7-8% without touching any equipment, just optimizing parameters they used to adjust by eye. Offshore operators who can simulate emergency responses before they occur. Maintenance teams who know exactly what will fail and when, scheduling repairs instead of reacting to crises.

Is the initial investment worth it? If you have critical assets where each hour of downtime costs tens of thousands of euros, it's not even a question. And if you're starting out, you don't need to digitize the entire plant from day one - start with a critical process, demonstrate value, and expand from there. The important thing is to start.